05/26/2016

No matter how hard we all try, not every landing is perfect. But thanks to landing gear struts, even a not-so-perfect landing doesn't break your airplane into pieces.

There are 4 primary types of landing gear struts, and all of them are designed to help take the 'shock' out of your landing. Here's how they work.

Rigid Struts

Rigid struts were the original type of landing gear. The idea was simple: weld the wheels to the airframe. The problem was the imperfect landing; a hard touchdown meant the strong shock load transfer went directly into the airframe. And the pilot and passengers definitely felt it.

Soon after, aircraft engineers started putting inflatable tires on aircraft, and the air softened the impact load. While it wasn't a perfect solution, it definitely helped.

While you don't see them as often these days, you can still find rigid struts on the ramp. Almost all helicopters use them, in the form of metal skids attached to the frame of the helicopter.

Spring Steel Struts

One of the most common landing strut systems on general aviation aircraft is the spring steel strut. If you've ever flown (or ridden in) a Cessna, you know what it is. These aircraft use strong, flexible materials like steel, aluminum or composites to help absorb the impact of a landing.

As your plane touches down, the springs flex upward, dissipating and transferring the impact load to your airframe at rate that (hopefully) doesn't bend your plane. Spring steel is popular because it's mechanically simple, typically lightweight, and needs little to no maintenance. Plus, if you were like me when I was learning to fly, you know they can really take a beating.

Bungee Cords

Bungee cords are often found on tailwheel and backcountry airplanes. One of the most popular examples, and one you've probably seen, is the Piper Cub.

Bungee cords are just that - a series of elastic cords wrapped between the airframe and the flexible gear system, allowing the gear to transfer impact load to the aircraft at rate that doesn't hurt the plane. While some aircraft use a donut-type rubber cushion, most of them use lots of individual strands of elastic material to dissipate the shock, like the one pictured below.

Shock Struts

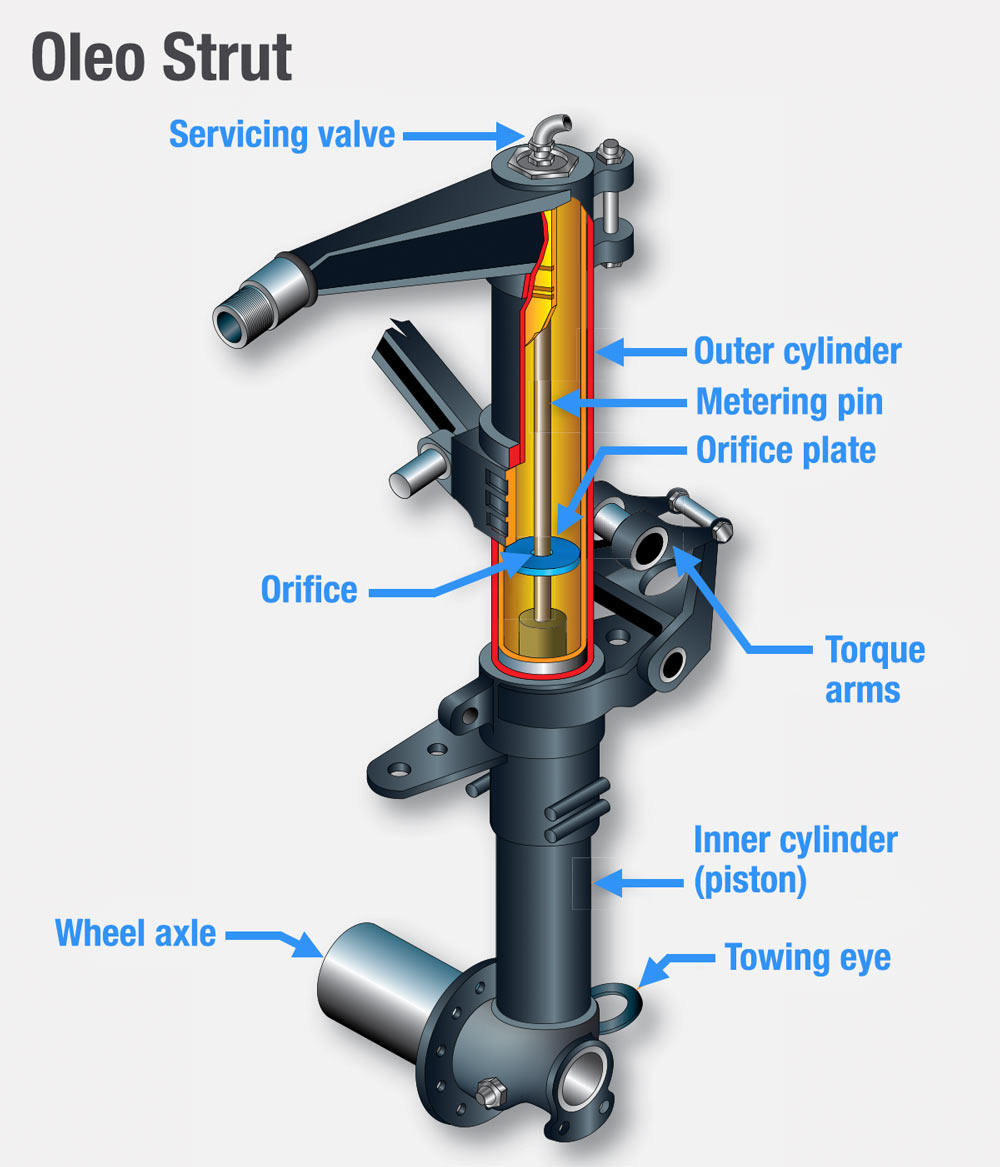

The last type of strut is the only one that is a true shock absorber. Shock struts, often called oleo or air/oil struts, use a combination of nitrogen (or sometimes compressed air) and hydraulic fluid to absorb and dissipate shock loads on landing. You can find them on some smaller aircraft, like the Piper Cherokee, but you most often find them on larger aircraft, like business jets and airliners.

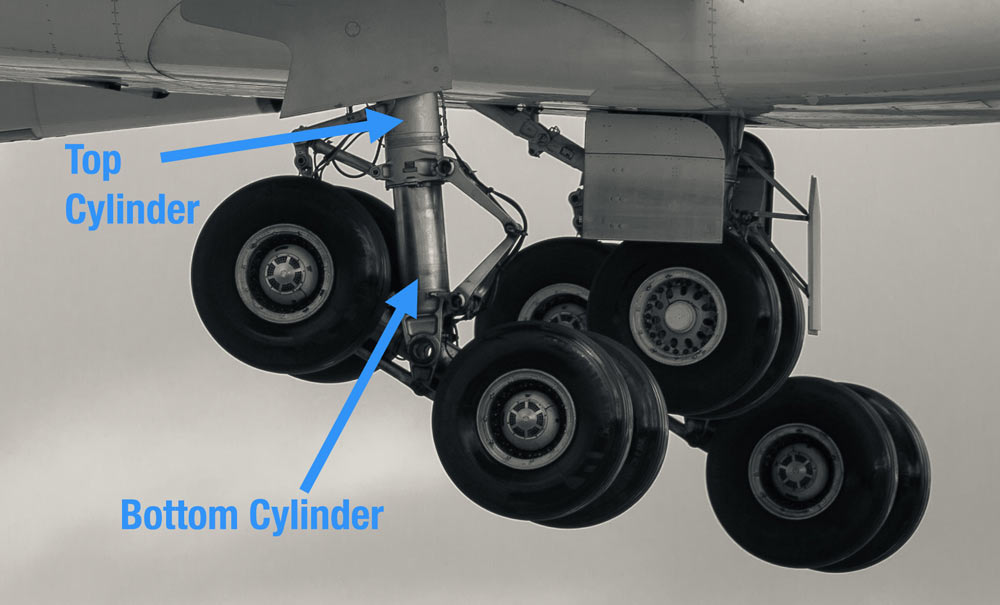

Shock struts use two telescoping cylinders, both of which are closed at the external ends. The top cylinder is attached to the aircraft, and the bottom cylinder is attached to the landing gear. The bottom cylinder, typically called the piston, can also freely slide in and out of the upper cylinder.

If you look at a cutaway of the two cylinders, what you almost always find is the bottom cylinder filled with hydraulic fluid, the top cylinder filled with nitrogen, and a small hole, called an orifice, connecting the two.

As you land, pressure from the wheels hitting the ground forces hydraulic fluid up through the orifice and into the top, nitrogen filled chamber. As the fluid moves through the hole (very quickly, by the way), it creates heat. And essentially, the kinetic energy of fast moving hydraulic fluid is transferred into thermal energy, and the shock of your touchdown is absorbed.

You can really see oleo struts in action when you watch airliners land. A perfect example was the Virgin Atlantic 747 that landed with one of its main gear up. The other three main gear struts took over and absorbed the landing, and you can see them compress on the touchdown.

No hay comentarios:

Publicar un comentario

Espero atento tus comentarios